Lesson 4: Using Surfaces to Define the Knee Joint#

The knee model developed in the previous lessons is obviously very

simple and does not resemble the geometry of a real anatomical knee very

well. However, AnyBody also contains facilities for development of more

realistic geometries of surfaces such as the femoral condyles, and we

shall explore those in this lesson. We start from the model developed in

the third lesson. If you did not manage to obtain a working model from

the third lesson, then please download a new one

here.

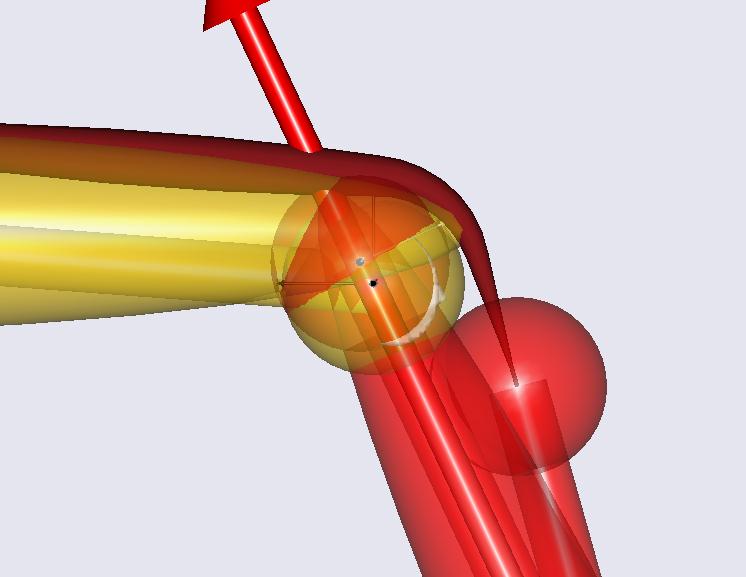

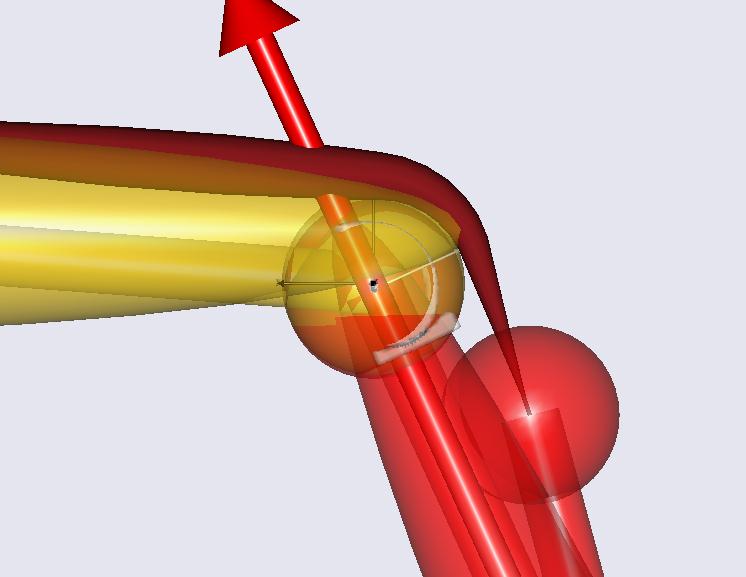

In this example, we are modeling the knee joint using some simplified 2-D implants (see picture) for the femoral head and the tibial plateau. To do this, we add some STL surfaces for theses implants to the model and use them to calculate a contact force, which changes the joint kinematics by making the implant surfaces slide along each other in the simulated motion.

Warning

Please note that if the surface has thin parts is a good idea to remove the backside of the surface so that it becomes open. This ensures that the forces will continue to grow as the surfaces are compressed into each other.

Due to the Force Dependent Kinematics (FDK), the joint axis for the knee moves as a function of external forces and muscle forces. In this lesson we want to have a closer look at this migration. Before inserting the implant, we relocate the position of the insertion node of the quadriceps muscle on the tibia back to the initial position.

AnySeg Shank = {

r0 = {0.8, -0.4, 0.0};

Mass = 4;

Jii = {0.4, 0.01, 0.4}*0.4;

AnyDrawSeg drw ={

Opacity = 0.5;

RGB = {1,0,0};

};

AnyRefNode KneeCenter = {

sRel = {0.0, 0.4, 0.0};

};

AnyRefNode Quadriceps = {

sRel={0.05, 0.3, 0.0};

};

};

We now start by adding an AnyDrawRefFrame to the KneeCenter node of the thigh

and the shank segments to show the migration. For the thigh segment we add the

following:

AnySeg Thigh = {

r0 = {0.4, 0, 0};

Axes0 = RotMat(pi/2,z);

Mass = 5;

Jii = {0.3, 0.01, 0.3}*0.7;

// This is the center of the nominal knee joint. Notice that

// the actual knee center will vary when we use FDK.

AnyRefNode KneeCenter = {

sRel = {-0.03, -0.4, 0.0};

AnyDrawRefFrame drw = {RGB = {0,0,0}; ScaleXYZ = 0.05 * {1,1,1};};

// Define a cylinder representing the femoral condyle. The quadriceps

// will wrap about this cylinder.

AnyRefNode SurfCenter = {

sRel = {0,0,-0.05};

AnySurfCylinder Condyle = {

Radius = 0.06;

Length = 0.1;

AnyDrawParamSurf drw = {

RGB = {0, 0, 1};

};

};

};

};

And we do the same for the shank:

AnySeg Shank = {

r0 = {0.8, -0.4, 0.0};

Mass = 4;

Jii = {0.4, 0.01, 0.4}*0.4;

AnyDrawSeg drw ={

Opacity = 0.5;

RGB = {1,0,0};

};

AnyRefNode KneeCenter = {

sRel = {0.0, 0.4, 0.0};

AnyDrawRefFrame drw = {RGB = {1,1,1}; ScaleXYZ = 0.05 * {1,1,1};};

};

AnyRefNode Quadriceps = {

sRel={0.05, 0.3, 0.0};

};

};

Hiding the blue cylinder and running the model again shows that there is a rather big distance between the knee center nodes of thigh and shank.

Now we start to add our new knee joint by adding the knee implant parts

to the model. We need the two STL files

simplefemoral.stl and

simpletibial.stl. First, we define the

femoral condyles as an AnySurfSTL inside the KneeCenter and add an

AnyDrawSurf object inside to also be able to see the geometry:

AnySeg Thigh = {

r0 = {0.4, 0, 0};

Axes0 = RotMat(pi/2,z);

Mass = 5;

Jii = {0.3, 0.01, 0.3}*0.7;

// This is the center of the nominal knee joint. Notice that

// the actual knee center will vary when we use FDK.

AnyRefNode KneeCenter = {

sRel = {-0.03, -0.4, 0.0};

AnyDrawRefFrame drw = {RGB = {0,0,0}; ScaleXYZ = 0.05 * {1,1,1};};

// Define a cylinder representing the femoral condyle. The quadriceps

// will wrap about this cylinder.

AnyRefNode SurfCenter = {

sRel = {0,0,-0.05};

AnySurfCylinder Condyle = {

Radius = 0.06;

Length = 0.1;

AnyDrawParamSurf drw = {

RGB = {0, 0, 1};

};

};

};

AnySurfSTL FemoralHead = {

FileName = "simplefemoral.stl";

AnyDrawSurf drw = {

FileName = .FileName;

Opacity = 0.5;

};

};

};

The geometry of the tibial plateau would be a little bit misplaced if we

would just add it the same way as the femoral condyles. To adjust it to the

right position, we add a new node SurfSTLCenter centered at the right

position and define the AnySurfSTL inside this node:

AnySeg Shank = {

r0 = {0.8, -0.4, 0.0};

Mass = 4;

Jii = {0.4, 0.01, 0.4}*0.4;

AnyDrawSeg drw ={

Opacity = 0.5;

RGB = {1,0,0};

};

AnyRefNode KneeCenter = {

sRel = {0.0, 0.4, 0.0};

AnyDrawRefFrame drw = {RGB = {1,1,1}; ScaleXYZ = 0.05 * {1,1,1};};

AnyRefNode SurfSTLCenter = {

sRel = {0.01,-0.04,0};

AnySurfSTL TibialPlateau = {

FileName = "simpletibial.stl";

AnyDrawSurf drw = {

FileName = .FileName;

Opacity = 0.5;

};

};

};

};

AnyRefNode Quadriceps = {

sRel={0.05, 0.3, 0.0};

};

};

When we now run the simulation and hide the blue cylinder in the knee center, we can see that the surfaces penetrate each other quite a lot, so just putting in the geometries into the model does not change anything except that the locations of the two implants are now visible.

Now, we want to make the surfaces slide along each other. Therefore, we

define a contact force that pushes the surfaces apart as soon as they

are in contact. We define an AnyForceSurfaceContact and place it just

below the definition of the Shank. For the definition an

AnyForceSurfaceContact, we have to specify the two contacting STL

surfaces (the first one is called master, the second is the slave

surface) and a pressure module. This pressure module is a constant

defining a linear law between penetration volume and force. In this

example we use a more or less arbitrary value for this module. Our

AnyForceSurfaceContact object looks like this:

AnyRefNode Quadriceps = {

sRel={0.05, 0.3, 0.0};

};

}; //END of AnySeg Shank

// Define a contact force between the STL surfaces of the femoral condyle and

// the tibial plateau to make these surfaces to make the surfaces slide along

// each other.

AnyForceSurfaceContact ContactForce = {

AnySurface &surfMaster = .Thigh.KneeCenter.FemoralHead;

AnySurface &surfSlave = .Shank.KneeCenter.SurfSTLCenter.TibialPlateau;

PressureModule = 5e7;

ForceViewOnOff = On;

};

The AnyForceSurfaceContact creates a 3-D force vector located in the

center of pressure whenever the volumes defined by the STL files

penetrate each other. If the volumes are not penetrating, these forces

just become zero.

Running the simulation now shows that the tibial plateau slides along the femoral condyle and the reference frames defined in the knee centers stay close to each other with minmal penetration.

You will experience that the simulation takes longer to run now. When running

simulations like this one, we can encounter that in many steps the system cannot

be solved with the requested error tolerance. The reason for this problem is

that small changes in the position can result in big changes in the contact

force. Possibilities to improve this behavior are to exchange the surface

geometries and use finer meshes or to use a softer contact by reducing the

PressureModule.

We are now done with this lesson. You can now play around with this

model by changing e.g. the pressure module to change the penetration of

the implants or the positions of the tibial part to change the motion.

If you couldn’t make your model run up to this point, you can find the

complete model here.

In Lesson5 we can see how this kind of joint can be included into an existing model based on an AMMR body model.